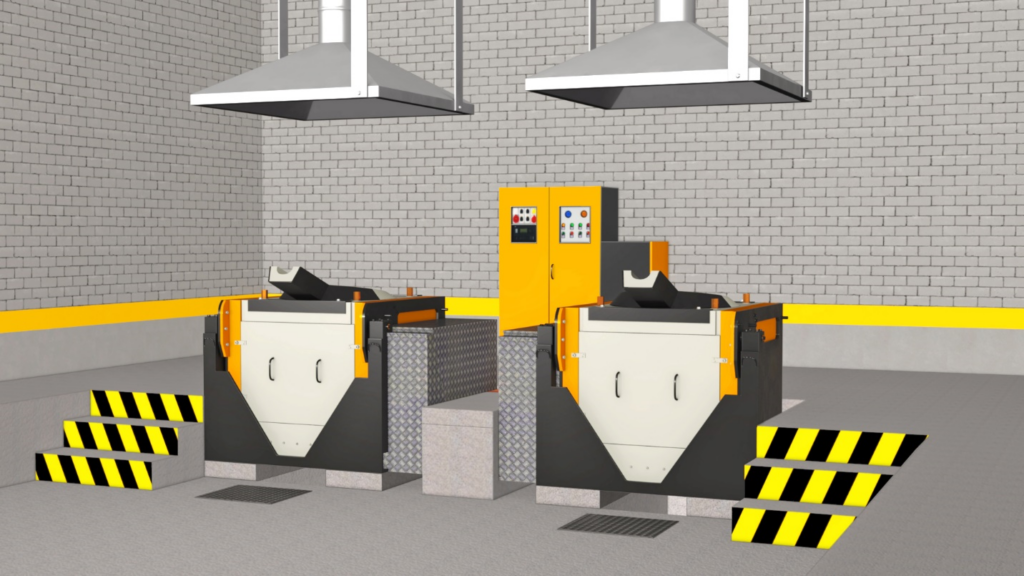

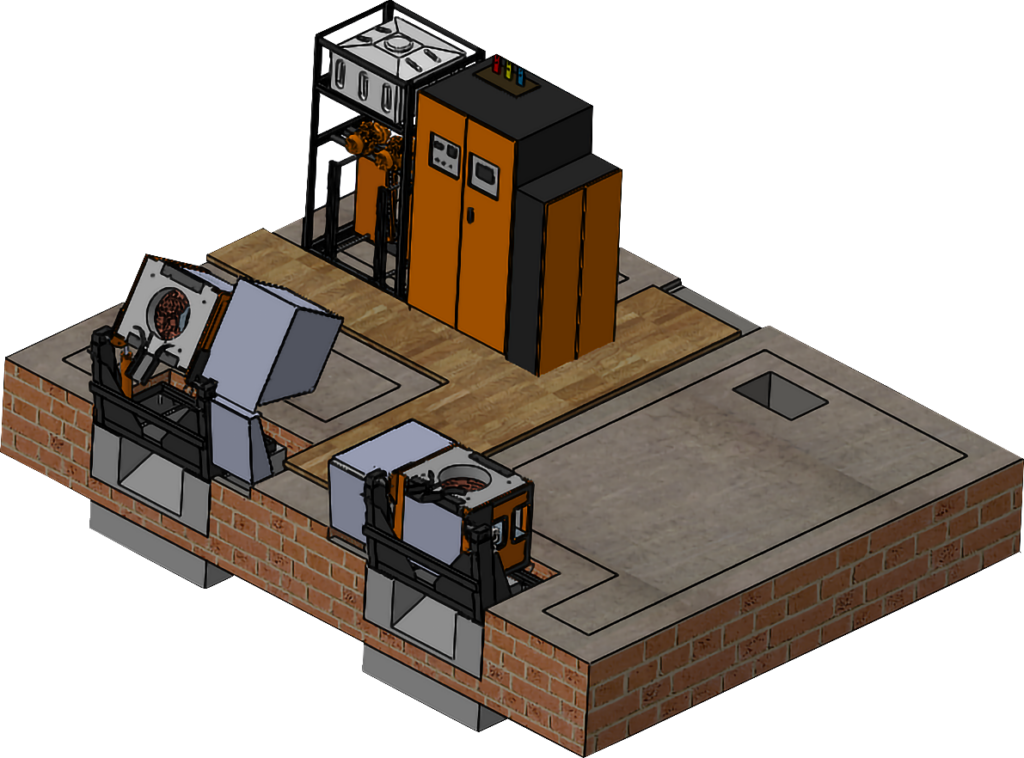

Manufacturers use an induction furnace to melt precious metals like gold and silver and its smelting precipitate/concentrate. Gold and Silver requires a furnace that will ensure high-quality products and has the capabilities to reach the high temperatures that are needed to melt the gold.

The induction furnace is safe and does not emit pollutants, making it the most favorable furnace for gold melting. It is also a heat and energy-saving process because there is no external source of heat required for melting as the heat comes from the charge itself.

Therefore, the gold and silver smelting induction furnace is one of the most preferred technologies for gold melting today. It has various features that make it stand out among other precious metal melting processes, which we will discuss today.

Induction Smelting Furnace Features

1. It is Versatile

The induction furnace is used to smelt, refine, and purify various precious metals, not just gold. You can use it to melt metals like copper, zinc, platinum, aluminum, silver, sand, tin slag, and rhodium. If you have a large-scale metal melting business, the gold and silver melting furnace will come in handy as the same furnace can be used on all the other metals you have and give excellent quality results.

2. It has a Very Fast Heating Speed

The other feature of the induction furnace that is quite significant is the heating speed. The furnace can melt gold quick, depending on the amount of gold you want to melt and the temperatures you have set for the process.

The good thing about the induction furnace is that you can easily control and adjust the melting speed. That allows you to work at the speed you want and at the best temperatures for your products.

3. It Has an Electromagnetic Stirring Effect

The stirring effect in the Induction melting furnace is an essential feature for any g products manufacturer because it helps with the consistency of the melt. It gives the molten metal structure and uniformity, keeping it pure, clean and of high quality.

The feature also helps reduce impurities and retain the controlled temperatures used in the process. With the electromagnetic stirring effect in play, you can be sure that your molten gold will have a uniform composition of the essential elements.

4. It Has a Wide Frequency Range

The other feature worth noting in the induction furnace is the wide range of frequencies. The melting frequencies range from 500 Hz to 100KHz. With the customization ability of most modern machines, you can manipulate the induction coil and the capacitor box to specific requirements and work within your preferred frequency range. That type of flexibility makes this type of furnace favorable for most precious metals in small and big melting establishments.

5. It Produces Low Noise During Smelting

Noise pollution is common in industries like metal melting because of the machines and the metals involved in the processes. However, the gold and silver melting induction furnace is one of a kind because it does not produce a loud noise.

The only sound you might experience during the gold melting process is a low that cannot compare to other manufacturing machines. The low noise feature allows operators to work in a conducive environment where noise pollution does not affect their productivity.

6. It is Environmentally Friendly

The world keeps moving towards environmentally friendly and energy-efficient solutions to save the rapidly deteriorating natural resources. The gold melting induction furnace is an example of a clean, energy-saving, and quiet solution in the metal melting industry.

With this furnace, you will not have any emissions of harmful gases and pollutants like bicarbonate and coal gas. Its thermal efficiency goes up to 95%, which is commendable and worth celebrating.

7. It is Safe and Reliable

The new technology of the induction furnace comes with protection features like overcurrent, short circuit, and overheating. All those features are automatic, alerting you when the machine has a problem that could be dangerous. These features protect you, your employees, and the products you are melting with the furnace.

8. It is Easy to Install and Operate

Nothing is as convenient as a machine that requires little effort and knowledge to put together and start using. The gold and silver melting induction furnace is one such machine that has an easy user interface and can be operated by almost anyone with little knowledge.

9. It Has a High Melting Efficiency

The other feature of the gold induction furnace is its high melting efficiency. You can be sure that the furnace will produce high-quality products because the procedure and technology it uses are efficient.

Although it does not require external heat sources, this furnace can reach very high temperatures to ensure that the metals melt entirely and consistently. It is one of those inventions that are good for the entire metal melting industry because of its high-efficiency levels.

Conclusion

The gold and silver melting induction furnace is ideal for various types of metals and has features that ensure your work is perfect for high-quality products. All the above qualities make the furnace an easy-to-use, clean, and affordable solution to melting precious metal.

If you were unsure about the induction furnace, we hope that the above features have convinced you of the power that the furnace has. Transform your business today by purchasing a customizable gold melting furnace.

For more information visit www.electroheatinduction.com.mx