Written by: Bart Forsyth, Oretest Drilling Mexico

The Decanter Centrifuge

In Oretest Mexico we have added SRU or Decanter Centrifuges to our mud system and moved the company forward into modern technology. These systems have been used in the oilfield for sometime on larger scales, and the manufactures have seen a market in the mineral exploration field and expanded. IMDEX/AMC has recently added the SRU to their rental fleet as additional equipment to use with their drilling fluids. At Oretest Mexico, we have taken it further and will have Centrifuges on all diamond drilling operations in Mexico.

So, what is a Centrifuge/SRU??

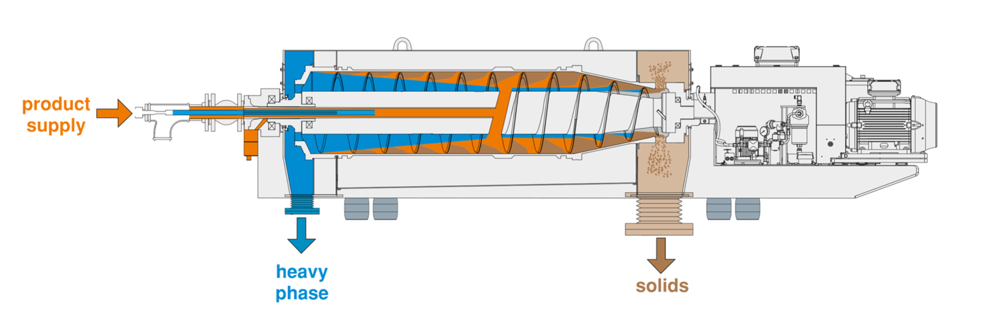

A Decanting centrifuge is a piece of equipment that separates

the suspended fluids using the principle of centrifugal action, the fluids with

suspended particles are pushed into the rotor drum through the inlet pipe and

the fluid hole of the spiral feeder. Under the influence of centrifugal force,

solid phase particles are pushed to the internal wall of the drum, then to the

mud exit of the small end of the drum by an internal slower rotating auger and

excreted. The fluids are excreted from the overflow hole of the large end. This

cycle is in order to achieve the purpose of continuous separation and a high

speed decanting centrifuge is effective for separation.

Drilling mud decanter centrifuges are designed specifically to remove unwanted solids and fine particles from virtually all kinds of used drilling mud, including those based on water/synthetics and conventional oil-based drilling fluids. Removal of up to 5 microns are achievable within certain parameters.

So what else does this system do to help me with my project??? The Decanter Centrifuge removes cuttings instantly out of your drilling muds, lets you use your water, and some of the drilling muds again and again. This saves you high water costs…and helps to cut down on cost of drilling additives. It also allows you to eliminate sumps, those big holes with lined plastic, cuttings and drilling muds that cost you a lot to reclaim.

So using this piece of technology we have given our clients easier sites to manage, smaller sites due to no sumps and saved water and water cartage costs.. All this for the same amount or slight increase in meter rates that other companies are charging.

Cuttings are collected in a plastic lined bay and removed from the drill site during drilling and at the end of the hole. The cuttings are bagged and removed from the exploration project.

This is the end result….This site was moved off the previous day upon completion of the drill hole.